Table of Contents

3D Printed Beehives - Pollen, Seeds and Seedpods

Intelligent Beehives is een nieuw project van AnneMarie Maes in samenwerking met Universiteiten uit Barcelona, Bristol en Bologna en met technische ondersteuning van het Sony Computer Science laboratorium in Parijs.

In dit art/science project worden state of the art oplossingen onderzocht die ondersteuning kunnen bieden in de strijd naar Colony Collapse Disorder, de grote verdwijnziekte die de belager is van de westerse honingbijen en tevens de oorzaak van een reductie van de biodiversiteit in het plantenrijk.

De Intelligent Beehive is interessant op verschillende niveaux: enerzijds bieden de gemonitorde guerilla beehives een bescherming voor kolonies van stadsbijen op de dool, anderzijds worden deze Intelligent Beehives door de acties van de bijen op hun beurt bio-sensors voor onderzoek naar het stedelijk ecosysteem (pollutie, pesticides e.a. via ontleding van pollen en bijen).

Bees as Architects: in dit project-onderdeel ligt de focus op het onderzoek naar 'bees as live 3D printers, dit in vgl. met de conceptuele design ontwerpen voor de Intelligent Beehive die in 3D geprint worden door echte hi-tech printers met bio-degradable materialen zoals chitosan, suiker of bijenwas. Een studie naar de mogelijkheden van bio 3D printing.

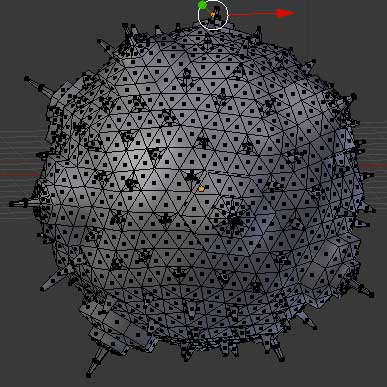

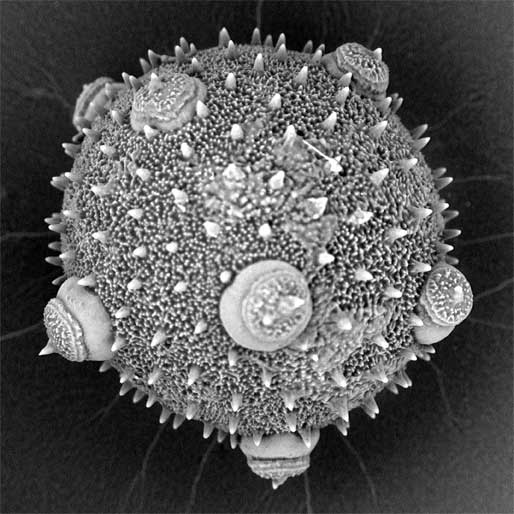

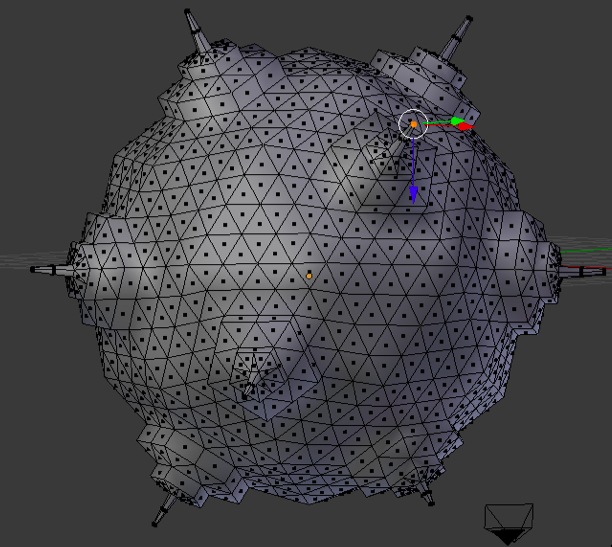

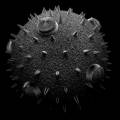

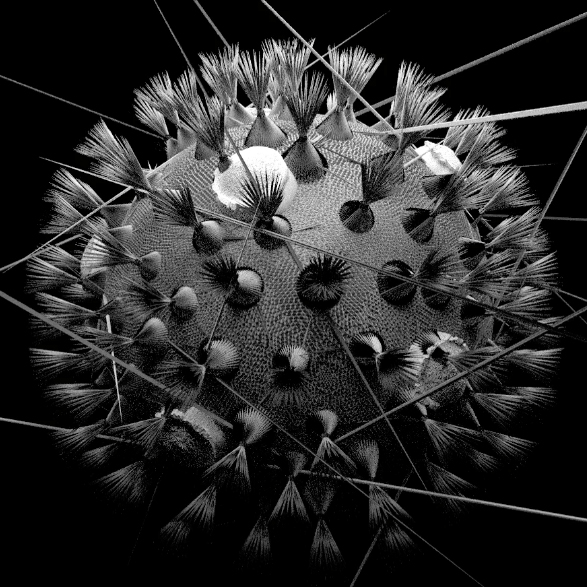

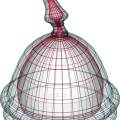

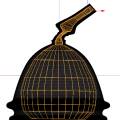

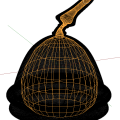

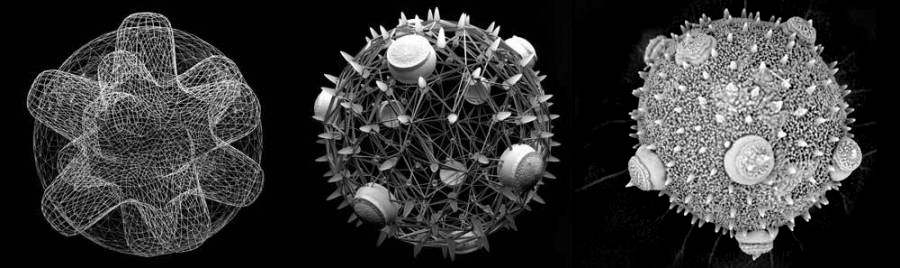

a Courgette-pollen inspired Beehive (Cucurbita pepo)

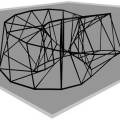

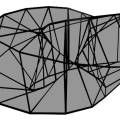

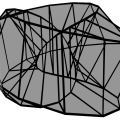

new renders, 3D research

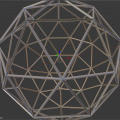

Biomimesis geinspireerde 3D modellen voor mogelijke Intelligent Beehives.

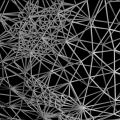

Van courgette-pollen over wireframe tot 3D modellen.

De courgette-pollen zijn verzameld door de bijen in de rooftop garden van het Brussels Urban Bee Lab, en zijn geoogst in de beehives.

Modellen dienen als inspiratiebron voor 'mogelijke Intelligent Beehives'; het is de bedoeling om stukjes van de 3D modellen in 3D te printen, als een soort 'reversed archaeology'en om in de 3D-geprinte modellen electronica (sensors etc.) te monteren.

courgette step by step, wireframe tests

courgette pollen - rendering

strange fruit

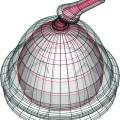

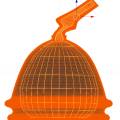

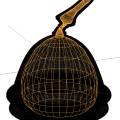

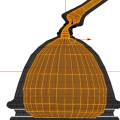

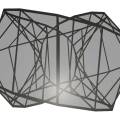

a Eucalyptus-Seedpod inspired Intelligent Beehive

Our research wants to use an artistic explorative method to investigate whether biomaterials from the hive (wax, propolis, honey, micro-organisms) can contribute to radical new ideas for future ‘intelligent’ beehives.

We want to build these Intelligent Beehives to support the merely domesticated bee colonies with suitable homes, as we, humans are responsible for the habitat loss of bee-swarms, due to our poor management of the environment, mainly by the use of pesticides.

Habitat destruction is the process in which natural habitat is rendered functionally unable to support the species present. In this process, the organisms that previously used the site are displaced or destroyed, reducing biodiversity.Habitat destruction by human activity is mainly for the purpose of harvesting natural resources for industry production and urbanization. Clearing habitats for agriculture is the principal cause of habitat destruction. Other important causes of habitat destruction include mining, logging, trawling and urban sprawl. Habitat destruction is currently ranked as the primary cause of species extinction worldwide. It is a process of natural environmental change that may be caused by habitat fragmentation, geological processes, climate change or by human activities such as the introduction of invasive species, ecosystem nutrient depletion, and other human activities.

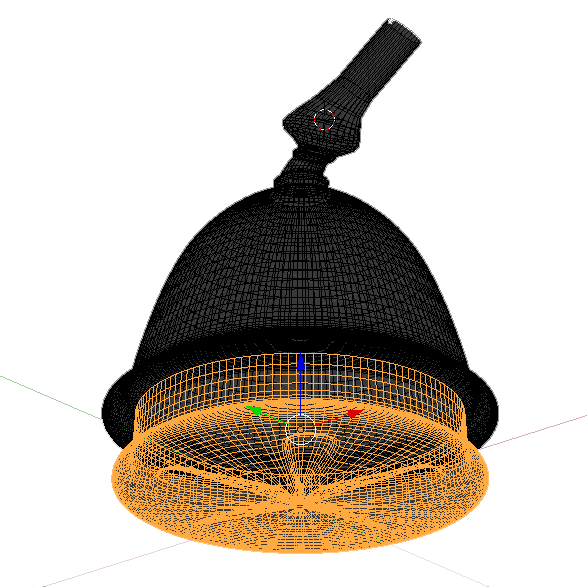

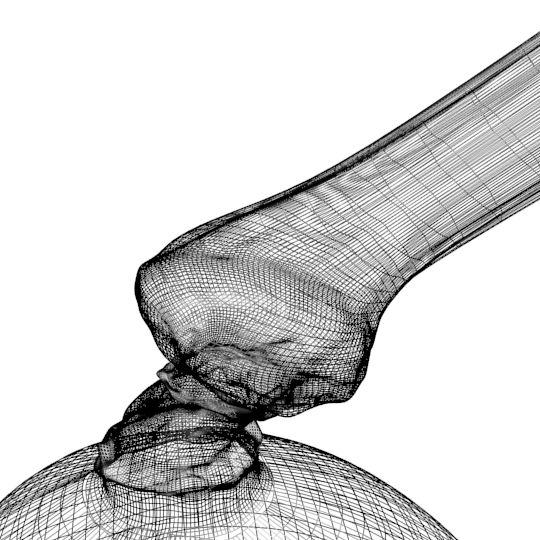

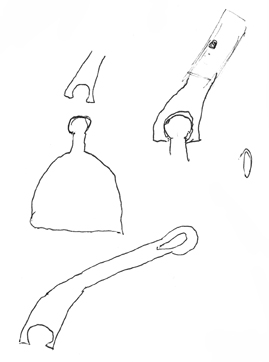

During my visit of Silicon Valley, I collected lots of eucalyptus seedpods in the park surrounding Stanford University. The seedpods are ± 25mm tall, and their rimmed morphology inspired me to start working on the shell of the intelligent beehive.

(± 7cm H)

Files prepared for 3D printing at i.Materialize, rendered in Polyamide Red and Black (polished and dyed).

The 'stem' is mobile and can be fastened as a clamp to a support in different positions.

The skin is insulated with a double layer filled with air, but with enough space to host the sensors.

The double 'rim' should give the possibility to extend or to shrink the hive when necessary, when the colony develops or when it's shrinking while preparing for wintertimes.

Files prepared for 3D printing at i.Materialize, rendered in Polyamide Red and Black (polished and dyed).

The 'stem' is mobile and can be fastened as a clamp to a support in different positions.

The skin is insulated with a double layer filled with air, but with enough space to host the sensors.

The double 'rim' should give the possibility to extend or to shrink the hive when necessary, when the colony develops or when it's shrinking while preparing for wintertimes.

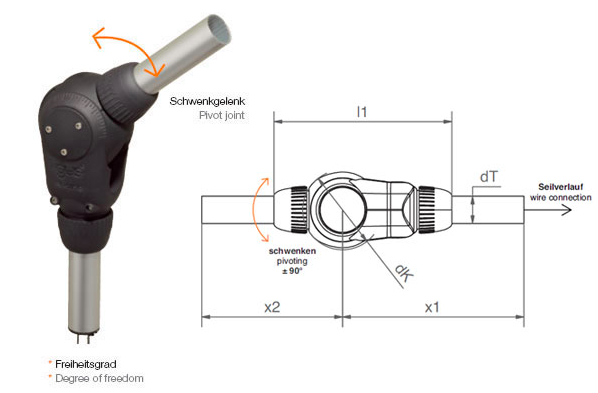

articulation/stem Eucalyptus seedpod — robotarm IGUS …………………. stem + ball 3D printed in polyamide, receiving hole printed in 3D rubberlike

Hive connection joint (kogellager) 360° freedom

3D printed in polyamide

Moebius Strip: 3Dprints in transparent resin and Bee artwork

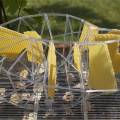

Finished Comb Construction

Bee comb construction ongoing.

Moebius Strip 3Dprinted in transparent resin at Materialise.

gadgets for a smartskin: plenoptic camera

For all its virtues, digital photography has yet to correct one age-old weakness: If you blow the focus, you've most likely lost the shot. An emerging lens system, known as plenoptics, will change that. The product of more than a decade of research from Adobe and institutions including Stanford and Indiana universities, plenoptic cameras capture multiple focal settings in one snap, so users can refocus after the fact. The German-made Raytrix R11 is the first mass-produced plenoptic camera available in the U.S.

Post-shoot refocusing requires a camera that captures thousands of separate paths of light. Plenoptic cameras have an array of micro-lenses on top of the image sensor; the R11 has 40,000. As light travels through those lenses, it fractures into 40,000 separate image fragments. Computer software decodes the files to compose a final image; adjusting the focus is as simple as moving an onscreen slider to tweak the depth of field. Photographers can also view two slightly different angles to create stereoscopic 3-D stills and video.

Such flexibility comes at a cost. The R11's final image resolution is only three megapixels, and video runs at six frames per second—pretty shabby given the camera's $30,000 price tag. In a few years though, that may change: Adobe is working on a version of Photoshop that will edit plenoptic images in anticipation of forthcoming consumer-friendly plenoptic cameras.

http://www.popsci.com/gear-gadgets/article/2008-03/one-camera-12616-lenses